TOYODA TRW is a major supplier of power steering pumps for the automotive market. We have only two downtime periods per year, so facility equipment has to run for six months with no interruption.

Contamination of the cooling water system was a continual problem, as anyone with cooling towers knows. Airborne particulate, microbiological growth, pollen, cottonwood and other materials collected in the cooling tower. Flowing through the pipes, the water picked up rust, iron chips, scale and other corrosion by-products. Combined, these particles reduced the efficiency of our heat exchangers and machines. It was a full time job for one person to clean individual machine strainers, filters and heat exchangers.

We investigated several types of filtration equipment, including sand filters, centrifugal separators, motorized filters and, finally, the Orival filters. We wanted an automatic, self cleaning filter which requires no external power, is able to remove particles of any specific gravity, even lighter than water, does not interrupt system flow, requires minimal maintenance and offers the lowest operating cost.

The Orival filter combines all of these qualities our first purchase from Orival was a 4″ Model OR-04-PE, rated at 350 gpm and equipped with a 120 micron fine screen. We started up this unit with little assistance from the engineering staff at Orival.

The filter was in operation for about 4 years, with absolutely no service requirements. Due to upsizing of the cooling water system, we needed a filter with a higher flow rate. To our surprise, Orival offered a trade in allowance for the old filter. We immediately purchased an 8″ unit, Model OR-08-BS, rated at 1320 gpm and equipped with a 100 micron fine screen and an automatic built-in by-pass.

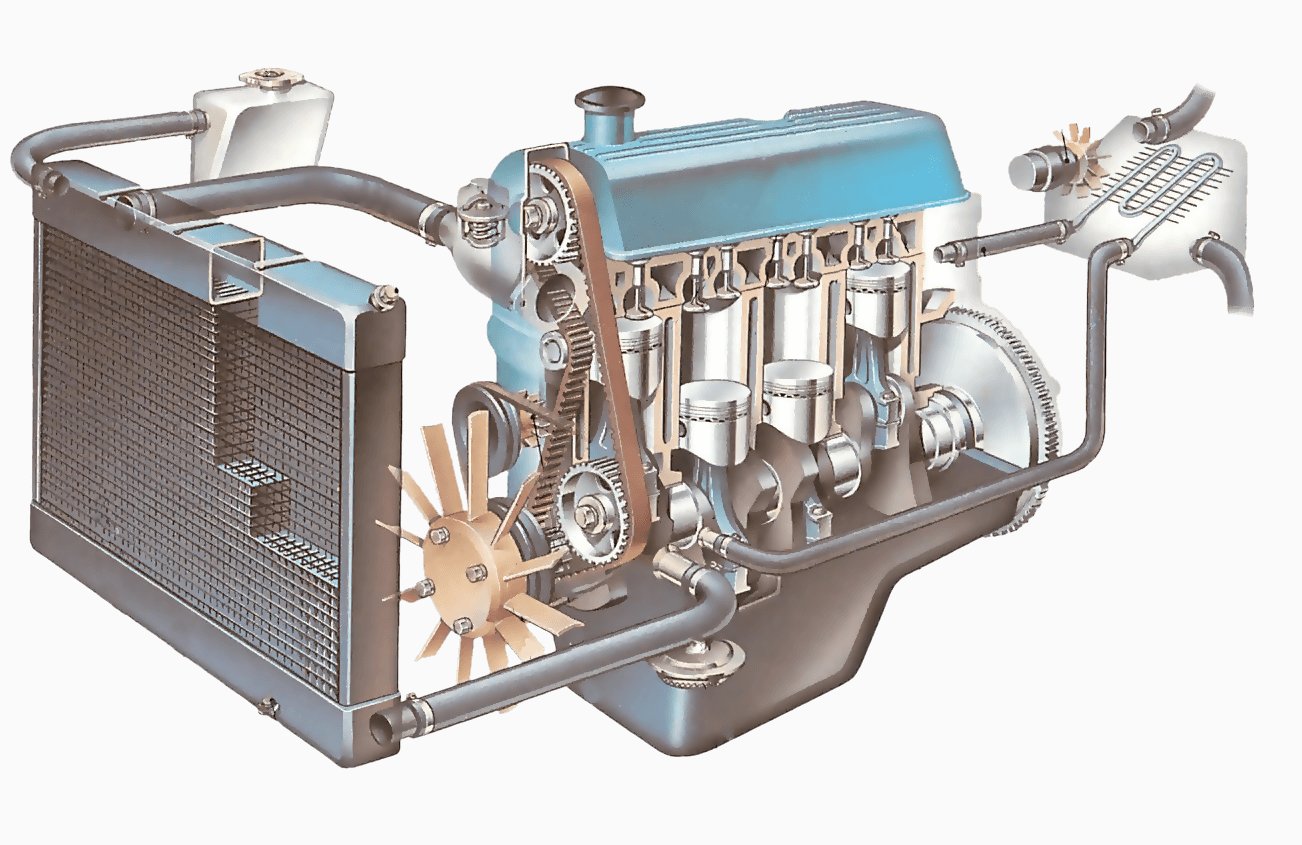

The 1320 gpm Orival Model OR-08-BS shown here removes all types of dirt down to 10 microns from cooling water systems

One of the advantages of the Orival filter is that, during operation, a layer of dirt accumulates on the surface of the screen. This layer of dirt actually removes much finer particles than the original screen itself. In fact, the 100 micron screen we are using is removing particles all the way down to 10 microns.

We no longer put strainers on individual equipment that needs cooling water. As matter of fact, we have even removed the strainers on the existing equipment.